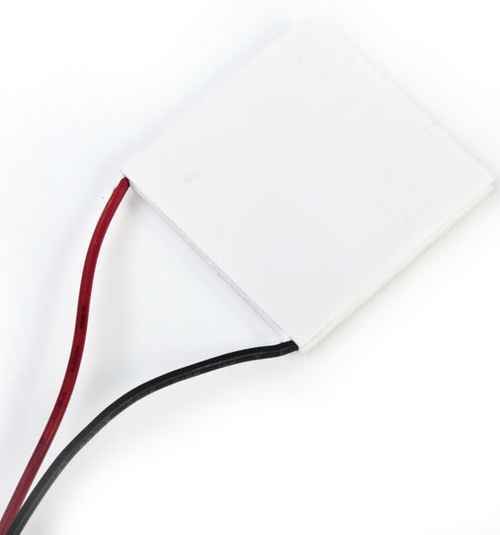

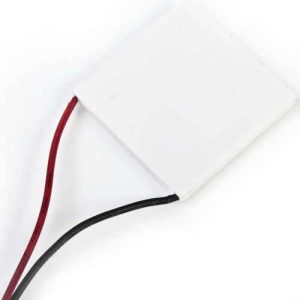

Generation chip size is 40 * 40 * 3.8MMThermoelectric power generation technology : how it works is to set a temperature difference between the ends of two different semiconductor properties , so in the semiconductor ends of the DC voltage is generated . Temperature difference between the semiconductor generation has no noise, long life and stable performance characteristics. Can quickly start at minus 40 ° in a cold environment , so more and more widely used in practical work .Thermoelectric power generation is a new way of generating , Sebel effect utilizing thermal energy directly into electricity . Thermoelectric power generation module manufacturing in semiconductor generators , as long as the temperature difference exists that is able to generate electricity . When work without noise , no pollution, the service life of more than ten years , maintenance-free , so it is a widely used portable power .Thermoelectric generators , mainly for oil, wild, military and other fields. Teledyne Inc. developed such as the US military , the oil with a special generator with annual sales exceeding one billion dollars. Another market-oriented areas of the project lies in the power plant for the use of solar energy, geothermal energy and other industrial waste , so that heat energy directly into electricity . In addition, the semiconductor power modules , small size, light weight, easy to carry , can be widely used in the manufacture of small household appliances , instruments , toys and tourism.First, the quality of the available test chip cooling a battery testMethods of operation are : one hand and hold both sides of the chip cooling , and refrigeration leads another piece by hand on the battery terminals ( red line by the positive electrode, the black line on the negative press ) , if you can feel Weileng side side micro heat , then cooling piece is good, normal work.Second, chip cooling refrigeration side is the side of the working state of fever, when cooling piece of work must give good thermal hot surface , is strictly prohibited without the cooling conditions for chip cooling is energized more than two seconds , causing overheating burned buyers own risk . Powered chip cooling hot swapping of hot and cold on both sides must be restored to room temperature ( typically takes five minutes or more ) can be carried out , otherwise easily lead to rupture of the refrigeration circuit chip damage and ceramic panels.Third, when the cooling plate is used as refrigeration , positive power supply red , black to negative power supply , power requirements using the ripple factor of less than 10% of the switching power supply. Generally welded wire panels that face the ceramic hot surface . If the negative power red wire , black wire to the positive power supply , the cooling of hot and cold face piece notes.Fourth, chip cooling heat sink surface when not installed , do not turn on the power ; hot surface temperature is too high will cause poor cooling limit temperature of 100 degrees cooler than the hot surface of the piece , which led chip cooling overheating burn. Because the refrigerator temperature difference between the hot and cold side piece is performed utilizing refrigeration , so the lower the hot surface temperature is lower cold temperature , the cooling effect will be better.Fifth, refrigeration piece is a combination of ceramic panels from both sides and semiconductor materials by low-temperature solder , the intensity is not high, is fragile, and the user must ask gently , do not bump, but can not fall from the sky next , to avoid breakage and damage to the ceramic panels .Six chip cooling model naming is composed of six parts . For example TEC1-12706Part I: TE expressed by thermoelectric cooling module , Thermo-Electric is the English abbreviation ;Part II: Structure category indicates refrigeration sheet , commonly used ceramic type refrigerators sheet (Thermoelectric element is greater than the cross-sectional area1mm2) Is represented by C , small ceramic type thermoelectric cooling module , also known as micro- electric cooling components (Thermoelectric element cross-sectional area ≤1mm2) With S said , there is a metal structure represented by M;Part III : Indicates chip cooling layers ( series ) , with an Arabic numerals , refrigeration piece of layers from one layer to 6 layers ranging from the more layers , the greater the difference in temperature .Part IV : Indicates chip cooling galvanic logarithm ( number of P, N nodes ) , with three Arabic numerals, such as 127 pairs.Part V : Indicates the current value of the maximum temperature refrigeration piece allowed with two Arabic numerals , such as 06 that means 6A current, this current is the load current limit threshold voltage optimal thermal state, when the refrigeration components temperature will result in a current value decreased .Part VI: indicates the status of the cooling surface of the chip , with no more than two of English letters. No metallization layer does not represent, sided with T said metallization layer , double layer metal expressed by TT .Seven , in practice , 127 series ( i.e. galvanic number 127 pairs ) of the cooling sheet is generally applied voltage is 12V. For example : TEC1-12706, limit the number of galvanic voltage i.e. 0.12 * 127 * 0.12≈15.4V, normal operating voltage of about 78% or 15.4 * 78% limit voltage = 12V, in the normal operating voltage of the operating current of about the maximum allowable current value of 78% that is 6 * 78% ≈4.7A, low voltage , low current is also higher chip cooling heat sink surface temperature , current is lower ; the largest piece of induced cooling cold power = galvanic current maximum allowable number * * 0.07 = 127 * 6 * 0.07≈53W; chip cooling temperature differences in the practical application and utilization of about 60% to 70% of the theoretical value , refrigeration tablets heat is cooling capacity of the cooling plate and the power and cooling sheet , then heating the sheet so that the refrigerating efficiency more than 100%

- کریستال و رزوناتور

- کانکتور و سوکت

- انواع ماژول

- المان های سرد کننده

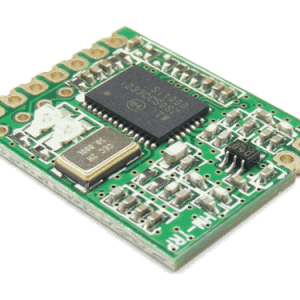

- ماژول های ارسال و دریافت Data

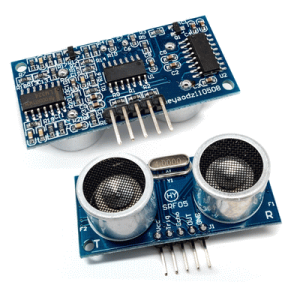

- ماژول های اولتراسونیک

- ماژول های بلوتوث

- ماژول های تشخیص حرکت

- ماژول های تشخیص گاز

- ماژول های تغذیه

- ماژول های حافظه

- ماژول های دما و رطوبت

- ماژول های رادیو

- ماژول های زاویه و شتاب سنج

- ماژول های شارژر باتری

- ماژول های شبکه

- ماژول های صوتی

- ماژول های مبدل و اینترفیس

- ماژول های GPS و GPRS

- ماژول هاي اثر انگشت

- ماژول های RFID

- ماژول های اپتیک

- درایور موتور

- دیگر ماژول ها

- بردهای توسعه و PCB

- آی سی

- Driver

- Converter

- ابزار و مواد جانبی

- ال سی دی و سون سگمنت

- انواع سنسورها

- خازن

- دیود

- رله و میکروسوییچ

- مقاومت

- تغذیه

- موتور ها

- ترانزیستور

- اپتوایزولاتور

- فیوز

- متفرقه

دیدگاهها

هیچ دیدگاهی برای این محصول نوشته نشده است.